MGI

Engine Surface Roughness

Service

Engine Surface Roughness

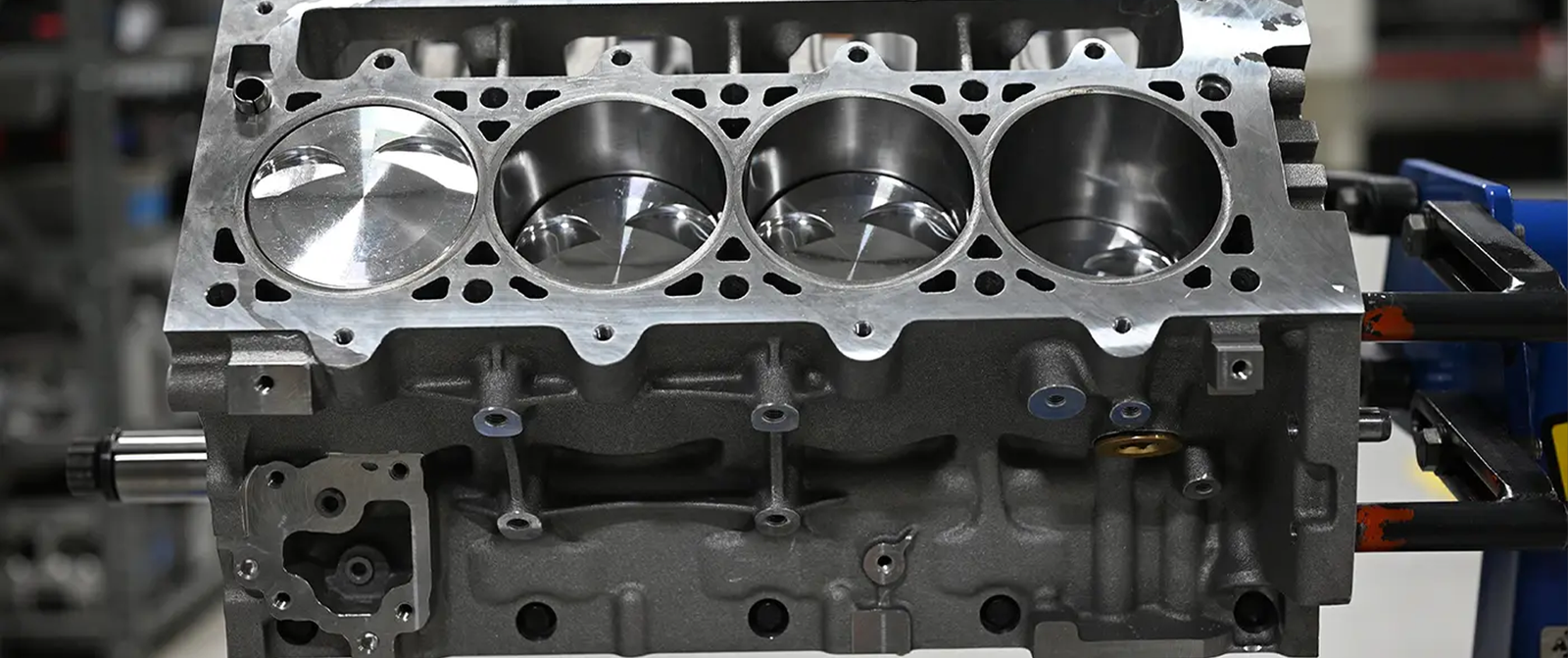

Ovality in cylinders is the difference between the measurements taken according to the width and length of the surface by rotating the dial indicator 90 degrees where it is. Since the rings will always contact the cylinder surface circularly, ovality on the cylinder surface makes it difficult for the engine oil to be scraped into the crankcase. Conicity is the difference between the measurements taken from the lower and upper parts by sliding the dial indicator up and down. In the case of conicity, the piston gap increases in one part of the cylinder and the piston is temporarily bent to one side.

Honing

The roughness of the surface resulting from the honing process is the most important factor determining engine life and oil consumption. Therefore, the cylinder surface must be smooth enough for the rings to operate without wear. At the same time, there must be an appropriate number, depth and distribution of oil pockets on the cylinder surface to hold the oil scraped by the rings. The rings operating on the smooth cylinder surface must be able to fully press the surface, scrape the oil well, and prevent gas leaks into the crankcase with increasing compression. The oil scraped by the rings must be able to hold on to the oil pockets on the surface and a minimum amount of oil must be carried into the combustion chamber.

get free appointment

The mgi agency must have a comprehensive diagnostic service that covers all areas of the vehicle.

call us now

+497322-9575928

Get an appointment

Get free royalties and appointments!